Case Coding : Squid Ink ( USA)

Large Character Printing

Squid Ink ( USA) provides industrial "Case coding" solutions which covers printing of variable alpha numeric data, barcodes, High resolution texts and graphical logo directly onto corrugated shipping containers, card board boxes, cartons and cases at the time of product packing. Both porous and nonporous packaging substrates are able to be case coded. Our case coding solutions eliminates the need for costly labels, minimizes the cost of product packaging, and results in a lower cost per mark.

2D coding and Hi Resolution printers

Squid Ink ( USA) Co pilot range of Hi Res printers provide quality 2D coding solutions which

covers QR code, Data matrix code ( 2 dimensional barcodes) etc. The difference between linear

barcodes and 2D codes is the type and amount of data they can hold. 2D codes are significantly

more traceable compared to barcodes as they can hold more data.

Squid Ink's Co Pilot Max printing system is designed to print superior quality hi Res characters on

porous surfaces. With up to 2.8" ( 70mm) of print height per print head and the ability to run up

to 2 print heads from one controller, the Co pilot Max offers a versatile, yet cost effective

solution for your coding and marking applications.

Thermal Inkjet Printers from Citronix ( USA)

Capable of printing high resolution graphics and codes at high speed, the ct 2000 series is suitable for a

wide range of applications ranging from food & beverages, pharmaceutical to industrial sectors. With

zero maintenance, high reliability and quick cartridge changeover, the ct2000 series help our customers

save valuable time and money. Featuring a 7" or 10" capacitive touch screen with an intuitive graphical

user interface, our printers are one of the easiest to setup and use in the industry.

With no maintenance and service requirements, our thermal inkjet range of printers offer the best value

for investment to our customers. Capable of printing highly resolution graphics and codes at high

speeds, using a range of inks, our printers can print on porous and non porous substrates. Using proven

and reliable HP Thermal Inkjet 2.5 Technology and automatic parameter settings using smart ink

technology we ensure you always have a reliable uptime.

Various Models and Number of print heads available:

- Ct 2200 : single print head

- Ct 2200 Pro: 2 print heads

- Ct 2400 Pro: up to 4 print heads

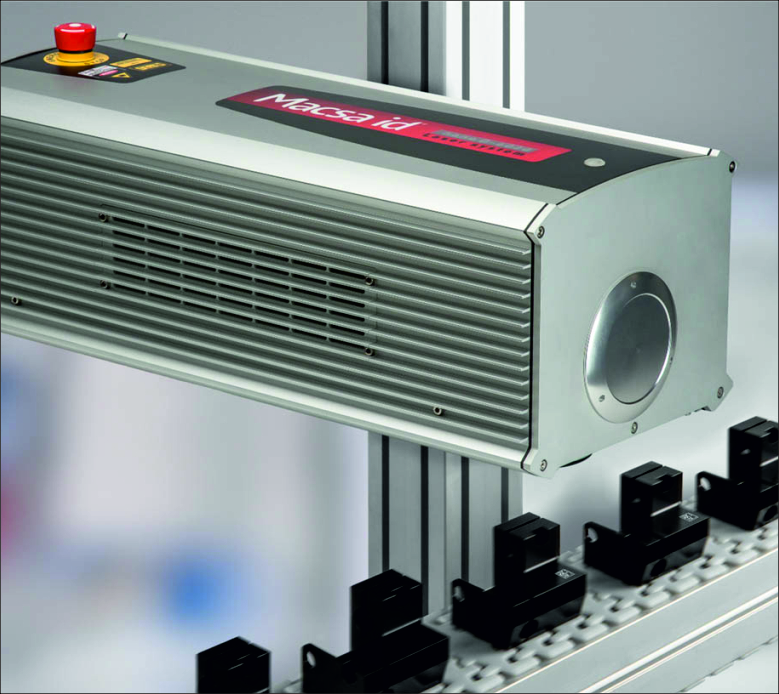

Laser Marking from Macsa ID (Spain)

- Innovative products Recognised as a world leader in technological innovation for Laser technology use in marking and coding.

- Solutions for all markets: Provide highly adaptable coding solutions suited to a wide range of materials and production environments.

- Guaranteed Product traceability Macsa coding systems enable products to be identified throughout the entire length of the supply chain, guaranteeing traceability.

Industrial Lasers

Macsa ID provides a range of high-quality industrial laser systems for a multitude of end users

and markets. Each allows the marking of text, data or graphics directly on to your product,

providing precision identification and traceability.

Built with high performance lenses, dual processors and our Vibration Compensation System

(VCS), Macsa ID industrial lasers are designed to deliver premium quality markings at high

speeds. Our laser systems are incredibly reliable, fast, flexible and can be adapted to harsh

production environments - negating the risk of costly downtime or reprints.

The incorporation of a 3D printing kit with each laser systems optimises the focus point across

any product or substrate. Additional support can be found through the use of our Marca

software, designed to support you in the smooth running of your Macsa ID laser system.

( can show pictures or video from web site for Nano DPSS,

Packaging Lasers

Macsa ID packaging lasers achieve high quality marking on any packaging material from cardboard to glass or PET to polystyrene. Our lasers require no consumables, making them environmentally friendly and cost effective to run. Macsa ID provides laser marking solutions which are compact for production line environments, but also modular options for flexible integrated applications, with both options being highly reliable and requiring little maintenance. Smart. Reliable. Versatile

CO2 lasers used in higher speed packaged goods applications including boxes, bottles and blister packs. They provide legible markings of the highest quality, which are permanent and sustainable in all production environments. Available in different enclosures in order to mark a wide variety of substrates such as cardboard, glass, ceramics, PET and PVC in the FMCG markets.

SPA2 C 10W, 30W and 40W CO2 lasers are widely used in packaged goods applications

including labels, boxes, bottles and blister packs. They are typically used to code paper and

board, glass and ceramics, coated materials, PET and PVC.

- 10.6, 10.2 and 9.3 wavelength lasers are available to

meet the coding needs of specific substrates such as

film and PET.

Hand Jet printers from EL REID ( Germany)

Mobile marking systems are particularly suitable for flexible use

Mobile marking systems, also often called handheld printers, make it possible to apply standardized texts and logos as well as individual data and barcodes to almost any surface.

Product benefits:

- Compact size, trouble-free product installation

- Simple and intuitive user interface

- Unique connectivity features

- High resolution 600 dpi printing

- Zero maintenance cost

- Extremely durable and high quality aluminium housing